In today’s pursuit of health and comfort, foot health is increasingly gaining attention. The production of traditional orthopedic insoles often relies on experienced technicians for manual measurements and customizations, which is time-consuming, labor-intensive, and difficult to meet precise personalized needs. However, with the rapid advancement of technology, the collaboration between foot 3D scanners and 3D printers is quietly revolutionizing the manufacturing process of orthopedic insoles, bringing an unprecedented custom experience to every user’s feet.

1. Technological Integration: A New Era of Precision Customization

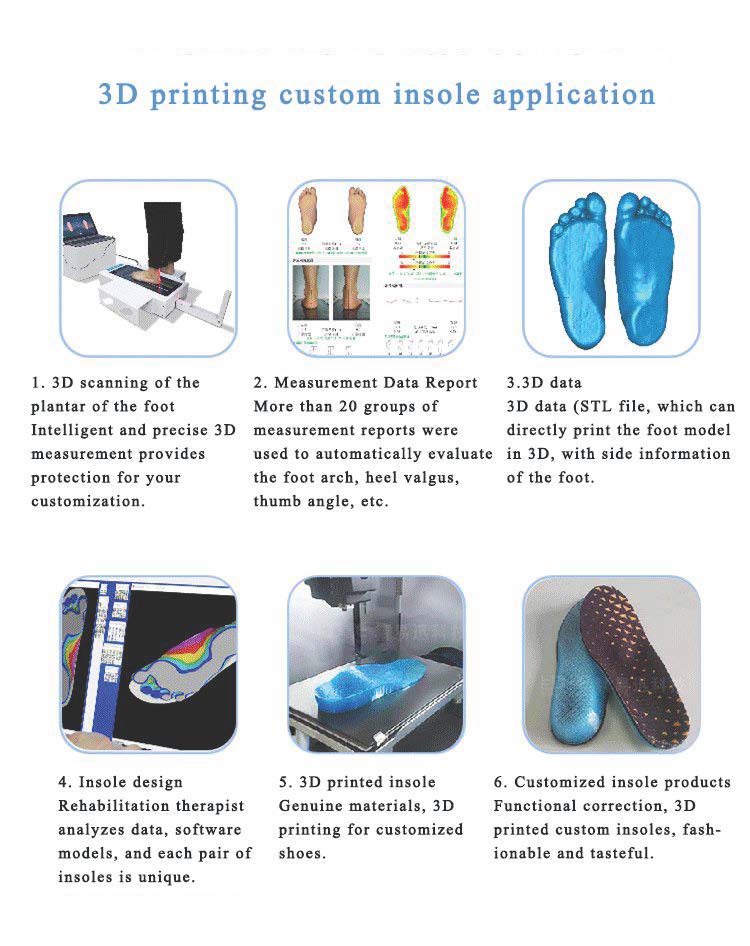

As the pioneer of this transformation, the foot 3D scanner utilizes high-precision, non-contact scanning technology to capture the user’s foot 3D data within seconds. This data includes key information such as arch height, foot length, foot width, and plantar pressure distribution, providing a solid foundation for the subsequent design of orthopedic insoles. Compared to traditional manual measurements, 3D scanning is not only faster and more convenient but also eliminates human error, ensuring the accuracy and objectivity of the measurements.

2. The Magic of 3D Printing: Personalized Customization

After obtaining accurate 3D foot data, this data is transmitted to computer-aided design (CAD) software for the precise design of the orthopedic insoles. Designers adjust the material, hardness, thickness, and support points of the insoles based on the user’s foot characteristics and needs to achieve optimal correction effects and comfort. The design data is then imported into a 3D printer, which materializes the virtual design into a physical orthopedic insole through layer-by-layer material deposition.

The introduction of 3D printing technology greatly enhances the level of personalization and manufacturing efficiency of orthopedic insoles. It can print insoles that perfectly conform to an individual’s unique foot shape, achieving true “one person, one insole.” At the same time, the flexibility of 3D printing means it can quickly respond to design adjustments and meet the diverse needs of different users.

3. Empowering Technology: Guardians of Healthy Living

Personalized customization of orthopedic insoles is not limited to addressing foot deformities such as flat feet and high arches but is also widely applied in areas such as sports injury prevention, gait improvement, and elderly foot health maintenance. Through scientific foot support and correction, it can effectively alleviate foot pressure during walking and running, reduce the risk of sports injuries, and improve overall quality of life.

Additionally, with the continuous integration of technologies like the Internet of Things (IoT) and big data, the future production of orthopedic insoles will become even more intelligent. For instance, wearable devices could collect users’ walking data and dynamically adjust the insole design parameters, achieving even more precise personalized customization. Or, through data analysis, potential foot health problems could be predicted in advance, offering users personalized health advice.

The collaboration between foot 3D scanners and 3D printers is not only a leap in orthopedic insole manufacturing technology but also a vivid example of how technology empowers healthy living. It demonstrates how technology can improve our quality of life and protect our health in more humanized and precise ways. In this era full of infinite possibilities, we have every reason to believe that with the continuous development of technology, more innovative products like orthopedic insoles will emerge to safeguard our healthy living.