In the ever-evolving world of fashion, the footwear industry, as an indispensable part, is undergoing unprecedented transformation. As consumer demand for personalization, comfort, and health continues to grow, traditional supply chain management models in the footwear industry face significant challenges.

The introduction of 3D foot scanners has undoubtedly injected new vitality into this industry. Not only has it revolutionized the concept of shoe design, but it also plays a pivotal role in supply chain management, leading the footwear industry towards greater precision, efficiency, and human-centricity.

1. Precise Measurement, Customization Trend

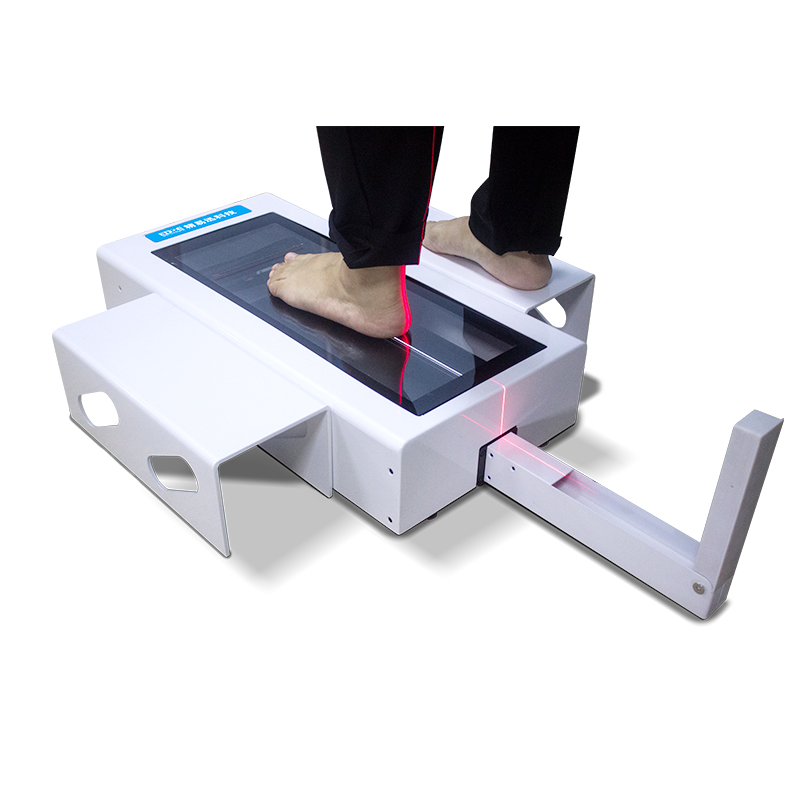

3D foot scanners use non-contact, high-precision laser or infrared technology to capture detailed three-dimensional data of a user’s foot within seconds. This data includes length, width, height, and subtle variations in arch shape. The application of this technology has fundamentally changed the way shoe sizes are determined, moving away from traditional methods based on experience or standard sizes to true one-to-one personalized customization.

At the front end of the supply chain, designers can use these precise data points to create shoe designs that better fit individual foot shapes, meeting consumers’ dual demands for comfort and personalization. This also provides brands with a new avenue for differentiated competition, attracting and retaining more loyal customers through customized services.

2. Optimizing Inventory, Reducing Costs

Inventory management has always been a significant challenge for footwear companies in traditional supply chains.

Due to the diverse foot shapes of consumers, along with seasonal changes and fashion trends, inventory overstock and stockouts are common occurrences.

The application of 3D foot scanners allows companies to predict demand for different foot shapes more accurately through big data analysis. This enables scientific production planning, reducing the risk of inventory overstock. Additionally, digital management enables companies to respond quickly to market changes, adjust production strategies flexibly, and effectively lower operational costs, thereby enhancing overall competitiveness.

3. Improving Efficiency, Accelerating Product Iteration

In the footwear supply chain, every link from design to production to sales is closely interconnected. Delays in any one of these links can affect the entire chain’s operational efficiency.

The introduction of 3D foot scanners simplifies the design process, allowing designers to make modifications and adjustments directly on 3D models, significantly shortening the design cycle.

Combined with advanced technologies like 3D printing, companies can quickly produce sample shoes for try-on testing, further accelerating product iteration. This efficient production model not only meets the rapidly changing market demands but also gives companies a valuable time window to seize market opportunities and gain a competitive edge.

4. Promoting Health, Focusing on Consumer Well-being

As health awareness increases, more consumers are paying attention to the impact of footwear on foot health. 3D foot scanners not only provide precise foot data but also, in combination with biomechanical principles, analyze key information such as gait characteristics and pressure distribution.

This information is crucial for designing shoes with health benefits, such as corrective shoes for flat feet or high arches, or custom-made sports shoes for athletes. By focusing on consumer well-being, companies can earn consumer trust and positive reviews, establishing a good brand image in the competitive market.

Conclusion

3D foot scanners, as an innovative technology in the footwear supply chain, are leading industry transformation with their unique advantages. They not only achieve personalization and precision in shoe design but also optimize inventory management, enhance production efficiency, and promote consumer health and well-being.

As the technology continues to mature and its applications expand, we have every reason to believe that 3D foot scanners will play an even more significant role in footwear supply chain management, driving the entire industry towards greater intelligence and human-centricity.