Application of 3D scanner foot measuring equipment in insole production

1. Introduction

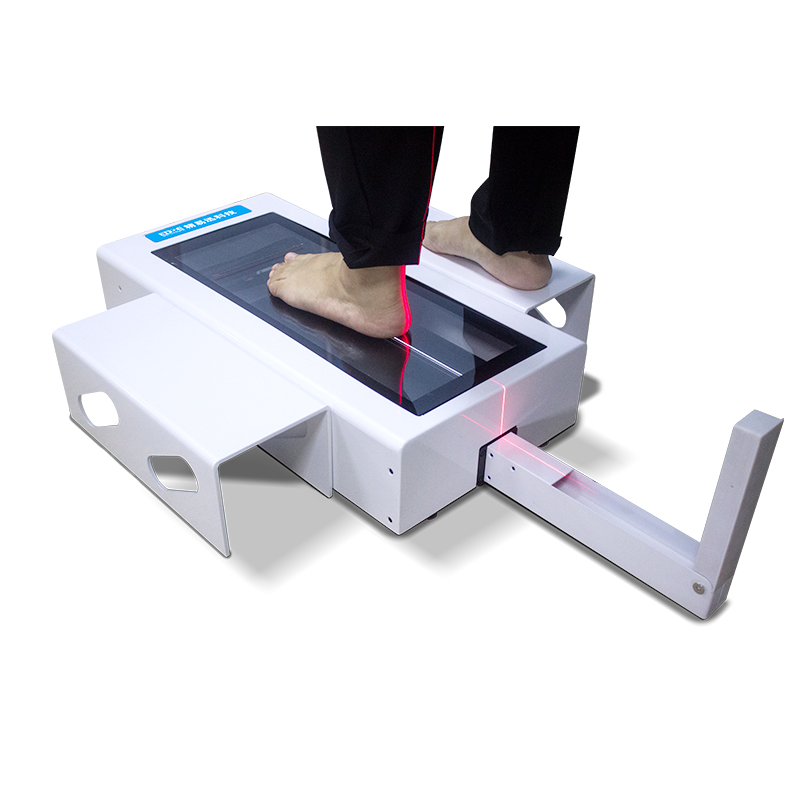

3D scanner foot measuring equipment is a high-tech tool for accurately measuring the three-dimensional shape of the foot. It is widely used in orthopedic medicine, footwear customization, sports rehabilitation and other fields. Compared with traditional foot measurement methods (such as plaster molding or footprint measurement), 3D scanning technology can provide high-precision, non-contact, and fast digital foot models, providing data support for the personalized customization of insoles.

With the integration of 3D scanning technology and CAD/CAM (computer-aided design and manufacturing) technology, 3D scanners have become an important tool for orthopedic insole production, providing a scientific basis for personalized foot orthopedics, sports optimization, and comfort improvement.

2. Working principle of 3D scanner foot measuring equipment

3D scanner foot measuring equipment obtains point cloud data of the foot surface through laser scanning, structured light scanning, optical measurement or depth camera technology, and reconstructs a high-precision three-dimensional model. The main technologies include:

Laser scanning technology (Laser Scanning): Use a laser beam to project onto the foot, measure the displacement of reflected light, and construct a 3D model.

Structured Light Scanning: Projecting a specific grating pattern onto the surface of the foot and calculating the three-dimensional shape based on light deformation.

Photogrammetry: Photographing the foot through a multi-angle camera and using an algorithm to reconstruct a three-dimensional model.

Depth Camera Scanning: Combined with infrared or ToF (time of flight) technology, measuring the depth information of the foot.

These scanning technologies can achieve millimeter-level accuracy, ensuring the accuracy of the customized insole data.

3. Application of 3D scanner foot measuring equipment in insole production

(1) Personalized insole customization

Traditional insoles mostly use standardized sizes and cannot meet the needs of different foot shapes. The precise data provided by 3D scanners enables insoles to be customized according to individual foot characteristics, improving comfort and orthopedic effects.

Obtaining foot data: 3D scanners record key parameters such as arch height, foot length, foot width, and sole pressure points.

Modeling and design: Adjust the shape of the insole through CAD software to match the individual foot anatomical structure.

3D printing or CNC processing: According to the model, 3D printing, CNC engraving or insole material molding technology is used to make exclusive orthopedic insoles.

(2) Accurate matching of orthopedic insoles

For patients with flat feet, high arches, inversion, valgus, diabetic feet, etc. who need orthopedic support, 3D scanning data can be used to analyze the force of the foot and design insoles that meet biomechanical requirements.

Optimization of orthopedic insole parameters: such as adjusting the arch support height, cushioning material thickness, calcaneal inclination angle, etc. to reduce abnormal pressure distribution.

Plantar pressure assessment: Combined with the plantar pressure measurement system (Plantar Pressure System), optimize the insole support area and improve gait stability.

Dynamic foot correction: Regularly scan and adjust the insole design to meet the needs of different rehabilitation stages.

(3) Performance optimization of sports insoles

In the fields of sports science and footwear manufacturing, 3D scanners can be used to analyze the characteristics of athletes’ feet to optimize the cushioning and stability of insoles.

Sports data analysis: Combined with gait analyzer, evaluate sports gait, landing method, and sole stress area.

Customized cushioning structure: Based on scanning data, different density materials are used to manufacture insoles to improve sports performance and reduce the risk of injury.

High-precision 3D printed insoles: Use different areas of material hardness (such as harder arch support area and softer forefoot buffer area) to optimize insole performance.

(4) Shoe manufacturing and mass customization

3D scanners are also used in shoe industrial production, especially in the high-end customized shoe market.

Rapid customer foot measurement: Provide customers with digital foot profiles to facilitate subsequent shoe customization.

Intelligent insole matching: Combined with AI algorithms, recommend the most suitable insole style and material based on scanning data.

3D database construction: Establish a foot database, optimize shoe last and insole design, and improve product adaptation rate.

4. Advantages of 3D scanning foot measurement technology

(1) High precision and objectivity

Compared with traditional manual measurement, 3D scanners can provide data with a millimeter-level error range, improve the accuracy of insole customization, and avoid human errors.

(2) Fast measurement and efficient production

Traditional plaster mold taking takes several hours, while 3D scanning usually completes the measurement within a few seconds to 1 minute, greatly improving the efficiency of insole customization.

(3) Data storage and traceability

3D scanning data can be stored for a long time, allowing customers to adjust the insole design at any time or compare rehabilitation progress.

(4) Combined with intelligent manufacturing technology

3D scanning data can be directly used in 3D printing, CNC engraving, and intelligent footwear manufacturing systems to improve the level of production automation and promote the development of personalized customization industry.

3D scanner foot measurement equipment provides high-precision, fast, and personalized measurement solutions for insole production, playing an important role in orthopedic medicine, sports science, footwear customization and other fields.

It combines digital modeling, 3D printing, and intelligent manufacturing technology to make the insole design more in line with the biomechanical requirements of the foot, improving comfort and health benefits. With the development of artificial intelligence and big data analysis, the future 3D scanning insole customization technology will be more accurate and efficient, providing a more scientific solution for foot health management.