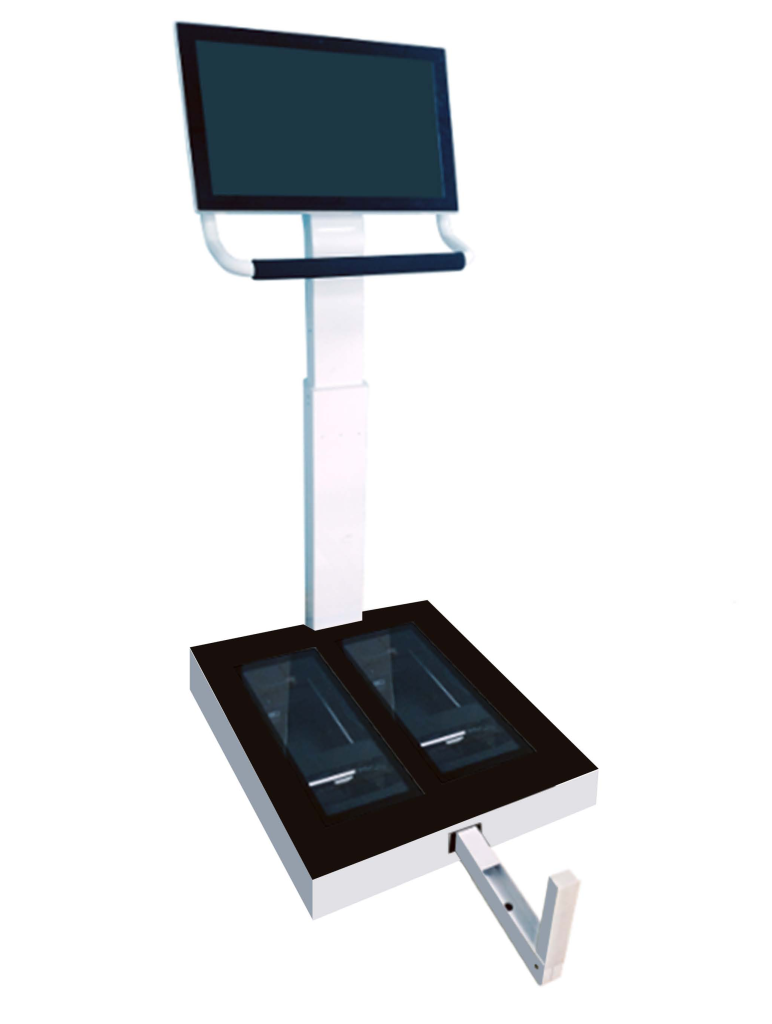

Flat foot detection instrument – efficient measurement of plantar 3D scanner

The plantar 3D scanner uses non-contact high-precision scanning technology to achieve rapid, accurate and data-based flat foot detection. Its efficiency is reflected in the following aspects:

I. Technical principles and core advantages

Non-contact laser/structured light scanning

Using laser or structured light technology, scanning can be completed without physical contact with the foot, avoiding errors caused by pressure deformation in traditional footprint measurement, while improving detection speed (single scan only takes 5-20 seconds).

Supports scanning in barefoot or socks, compatible with different detection scenarios, and adapts to the needs of various groups such as children and adults.

Millimeter-level accuracy and 3D modeling

Capture the surface details of the foot with a high-resolution sensor, with a measurement accuracy of up to 0.5mm, accurately obtain morphological parameters such as foot length, foot width, arch height, and distinguish abnormal foot types such as flat feet, high arch feet, and heel inversion and inversion.

Generate a three-dimensional plantar model to intuitively display the degree of arch collapse and the three-dimensional structure of the foot, and assist doctors in rapid diagnosis.

Automated data analysis and report generation

After the scan is completed, the system automatically extracts dozens of foot parameters (such as arch angle, pressure distribution), and generates a test report containing 3D models, heat maps and quantitative indicators, which takes only 1-2 minutes.

Supports comparative analysis with the database, quickly matches corrective insoles or shoe size recommendations, and improves personalized service efficiency.

2. The actual embodiment of efficient measurement

Simplified testing process

Traditional testing relies on manual visual inspection, plaster molding or X-rays, which is time-consuming and complicated to operate; the three-dimensional scanner only requires the patient to stand in the scanning area and complete data collection within 20 seconds, greatly shortening the testing time.

The scan data can be stored for a long time and supports historical comparison, which is convenient for monitoring the development trend of the arch or rehabilitation effect (such as the improvement of the arch shape after the use of orthopedic insoles).

Cross-domain application collaboration

Medical rehabilitation: Combined with 3D printing technology, the scan data can be directly used to customize personalized orthopedic insoles or corrective shoes, shortening the production cycle to a few hours.

Footwear customization: Scan data can be seamlessly connected to the CAD/CAM system to optimize the shoe last design and improve the fit and comfort of shoes.

Pingback: Foot Scanner_Foot Shape Scanner_Gait Analysis Equipment_Gait Analyzer Manufacturer_Gait Analysis System