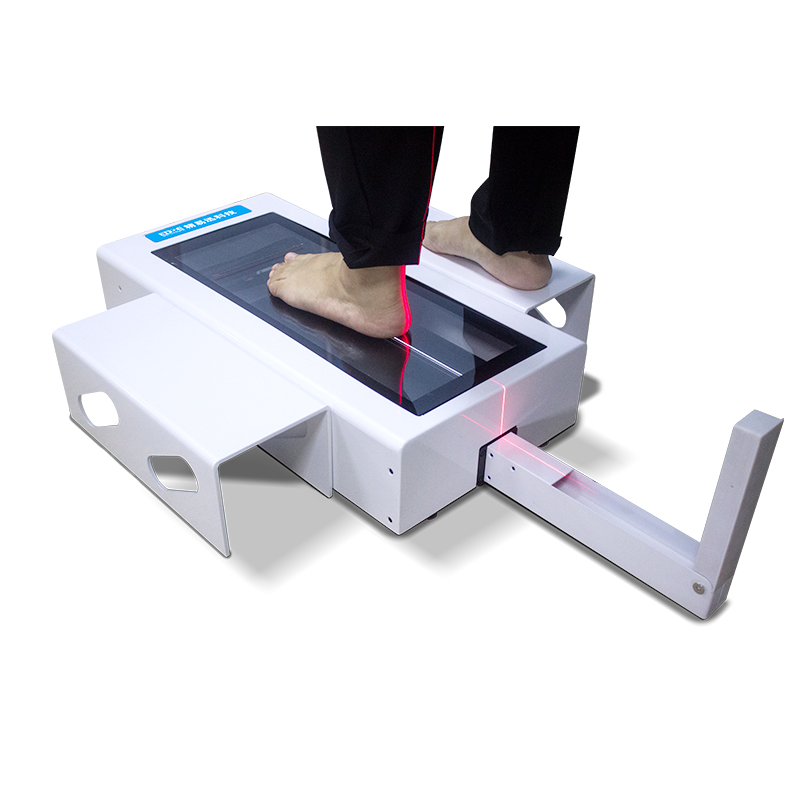

The general process of corrective design of insoles through plantar 3D scanner and 3D printer is as follows:

1. Obtain data such as foot size through plantar 3D scanner.

The plantar 3D scanner generally takes only 3-20 seconds to obtain more than 20 sets of data on the plantar, including foot length, foot width, foot height, arch height, heel tilt and other data.

The entire test process is very simple to operate, non-contact scanning measurement, intelligent voice guidance operation, convenient, safe and accurate.

The data is highly accurate, with an accuracy of up to 0.5mm, and the data is also rich, which can fully meet the data requirements of customized shoes and customized insoles.

2. Obtain data such as plantar pressure distribution through the plantar pressure distribution system. (Optional step)

Through the plantar pressure distribution system, you can obtain data such as changes in plantar pressure distribution, gait cycle, changes in support and position, and stride.

These data can further design the function of corrective insoles, especially for the design of personalized corrective insoles for rehabilitation patients and athletes.

3. Design work through insole design software.

Import the data obtained by the plantar 3D scanner into the corrective insole design software.

The designer then designs and adjusts the plan based on the measurement report of the 3D scanner and the plantar pressure distribution data of the plantar pressure distribution system, and designs personalized and functional insoles.

4. Make insoles through 3D printers.

After the designer designs personalized insoles according to user needs, he exports the designed data from the software, and then imports the data into the 3D printer through a USB flash drive or other methods.

After the 3D printer is set up accordingly and the appropriate material is selected, the corrective insole suitable for our feet can be printed.

5. Post-processing and trial wear debugging, etc.

After the production is completed through the 3D printer, the edges of the prepared insoles need to be polished and a comfortable layer, such as leather or foam, needs to be attached to the surface.

After it is done, let the user try it on, and then adjust it according to the user’s feedback to achieve the best effect.