Have you ever bought a pair of shoes that look good, but are always uncomfortable to wear? Or do you have sore soles after standing or walking for a long time, but can’t find a truly effective way to relieve it? In fact, the problem is often not the shoes, but the insoles.

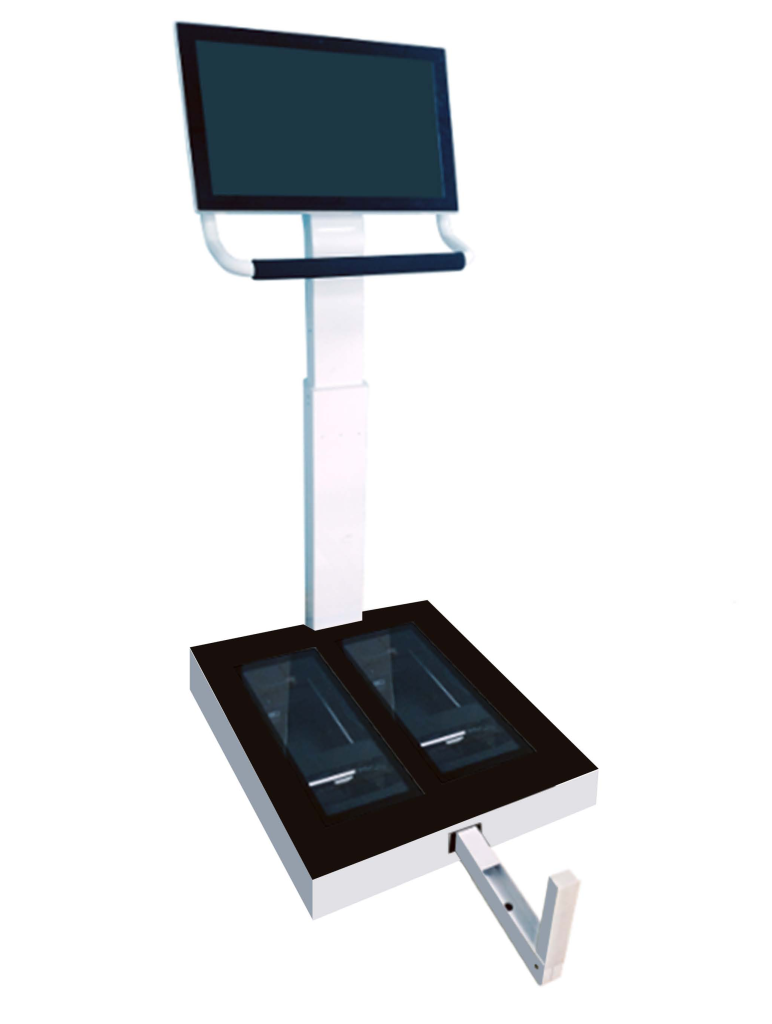

Traditional insoles are mostly made of standard molds, ignoring the individual differences in the structure of each person’s sole. Now, with the development of technology, a high-precision device, a laser 3D sole scanner, is providing a more professional and comfortable solution for customized insoles.

What is a laser 3D sole scanner

A laser 3D sole scanner is a device that uses laser projection and imaging technology to perform high-precision modeling of the sole contour. It can obtain a three-dimensional structural diagram of the user’s sole within seconds, including arch height, heel shape, foot size and other key parameters.

These data are widely used in the entire process of customizing insoles, realizing the true meaning of “foot-to-foot customization”.

Compared with traditional methods, what are its advantages?

1. Non-contact scanning, fast and comfortable process

Users only need to take off their shoes and stand on the scanning platform to complete the 3D imaging of the entire sole in a few seconds, without touching the skin, without ink or mold, especially suitable for children, the elderly or people with sensitive feet.

2. High-precision modeling, more accurate data

The error of laser scanning is usually controlled at the millimeter level, which is far superior to manual measurement and foot print technology. It can accurately identify the unique details of each sole, such as hallux valgus, arch collapse or heel valgus, providing accurate basis for insole design.

3. Personalized analysis to match different needs

Whether it is daily commuting, long-term standing, or high-intensity sports such as running and basketball, different activities have different requirements for insole support, shock absorption, and stability. The multi-dimensional data provided by laser scanning can make insole design more targeted and functional.

4. Data visualization, more intuitive user experience

Scanners are usually equipped with image analysis systems, so users can intuitively see their own sole structure diagrams, understand their foot type, force distribution, etc., which helps to improve health awareness and cooperate with long-term intervention.

5. Digital production to improve efficiency and consistency

Scanning data can be directly imported into the insole CAD design system, combined with 3D printing or CNC processing technology to achieve rapid customization and mass production of insoles. This not only improves production efficiency, but also reduces human errors, so that each pair of insoles can accurately match the user’s foot shape.

Wide range of applicable people

Laser 3D scanning customized insoles are not only suitable for people with foot problems, such as flat feet, high arches, diabetic feet, etc., but also suitable for ordinary people for daily health care and sports protection. Especially for people who stand or walk for a long time, such as teachers, medical staff, couriers, athletes, etc., wearing suitable insoles for a long time can effectively reduce fatigue and prevent chronic foot diseases.