In foot health management and rehabilitation correction, personalized insoles have gradually attracted people’s attention. Traditional insoles are usually made based on experience, and it is difficult for them to fully fit the individual characteristics of the foot. Moreover, with the continuous development of modern technology, the combination of foot pressure plates and 3D printers provides a scientific, accurate, and effective solution for the production of corrective insoles.

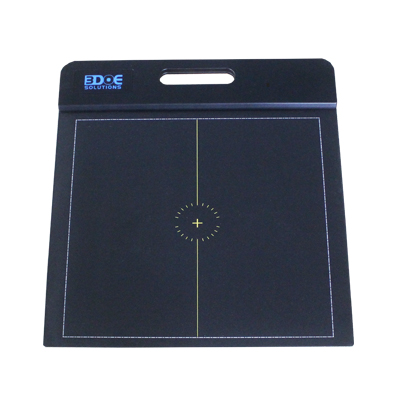

1. Foot pressure plate provides accurate data

The core function of the foot pressure plate is to detect the distribution of force on the sole during standing and walking.

- Static detection: records the pressure in each area of the sole, and evaluates the height of the arch and the left-right balance.

- Dynamic detection: during walking or running, obtains gait trajectory, center of gravity movement path, and changes of force center.

This batch of data can clearly show which areas are subjected to excessive force and which areas lack necessary support. For example, patients with flat feet often have obvious pressure concentration in the arch area, while high arches may show prominent pressure in the forefoot and rearfoot. Doctors and technicians can clearly understand the individual’s foot problems through the foot pressure plate, and then provide scientific evidence for insole design.

2. 3D modeling and design part

After obtaining the plantar pressure data, the next step is to convert this information into a three-dimensional design model. Generally, it is required to be combined with data from a foot-shape 3D scanner.

The scanner provides foot shape and size, such as foot length, foot width, instep thickness, and arch height.

The pressure plate provides force distribution and gait characteristics.

When the two are combined, designers or related professional software can create an insole model with personalized characteristics. Taking the collapsed arch area as an example, the support height in the model will be increased, and for areas with concentrated plantar pressure, thicker or harder materials will be adopted to disperse the pressure, so as to achieve precise correction.

3. 3D printing and personalized manufacturing

After the insole model is completed, it can be produced by a 3D printer. Compared with traditional mold production, 3D printing has several significant advantages:

- Personalization: each pair of insoles is uniquely designed and completely customized according to the individual’s foot shape and pressure distribution.

- Flexibility: different materials can be selected for different groups of people, such as soft TPU suitable for daily wear, while harder materials are suitable for patients requiring strong correction.

- Rapid iteration: if adjustments are needed after trial wear, it only requires modifying the model and printing again, without the need to reopen molds.

- Precise reproduction: the curvature, thickness, and hardness distribution of the insoles can all be accurately displayed according to the design plan.

4. Application value and significance

The combination of foot pressure plates and 3D printing technology has brought corrective insoles into the true era of “digital customization.”

In medicine, it provides effective support and protection for patients with flat feet, valgus feet, and diabetic feet, reducing pain and the incidence of complications.

In the sports field, it helps athletes optimize gait, enhance stability, and reduce the risk of injury.

In daily life, it provides comfortable support for people who need to stand or walk for long periods, improving quality of life.

In addition, this digital process also facilitates data storage and tracking. After a period of time, users can undergo testing again, compare the changes in plantar pressure before and after, evaluate the corrective effect of the insoles, and make further adjustments.