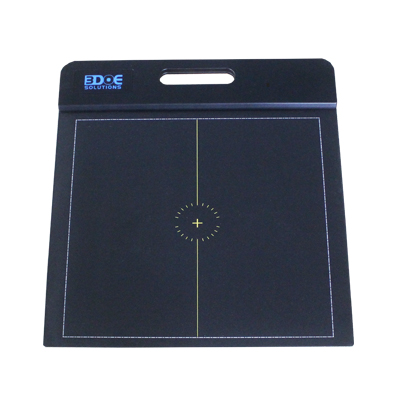

The plantar pressure plate primarily records the pressure distribution of the sole under static or dynamic conditions by arranging dense pressure sensor units on the platform surface.

The sensors usually adopt piezoresistive, piezoelectric, or capacitive forms, converting mechanical stress into electrical signals. After amplification, analog-to-digital conversion, and digital filtering, a time-resolved pressure matrix is obtained.

Based on this matrix, peak pressure, average pressure, pressure–time integral, contact area, and center of pressure trajectory can be calculated to objectively represent the load on each foot region and the gait phases.

In custom insole design, the processing of plantar pressure data provides direct guidance.

By identifying high-pressure concentration areas and regions of long-term load accumulation, the positions that require pressure reduction can be determined, and corresponding materials and thicknesses can be selected to achieve local cushioning.

Through the analysis of arch load-bearing and center-of-pressure movement, the arch support contour and forefoot propulsion structure can be designed to improve the accuracy of foot force lines.

Dynamic comparative testing can verify the redistribution of pressure before and after insole modification and evaluate the therapeutic effect or the results of training interventions.

In addition, plantar pressure measurement also has value in clinical risk management and the optimization of athletic performance. For patients with diabetic foot or postoperative recovery, quantitative monitoring can reduce the risk of ulcers and recurrence.

For athletes, the stiffness and elasticity of insoles can be optimized based on pressure and time parameters to improve propulsion efficiency and prevent stress-related injuries.

It should be noted that measurement results are affected by sensor resolution, sampling frequency, measurement conditions (barefoot or in-shoe), and gait consistency. Therefore, in custom insole design, clinical assessments and multimodal gait video data should be comprehensively considered. Finally, the pressure field information is converted into insole parameters such as local thickness, material modulus, and support contours to achieve a scientifically reproducible customization plan.

It is also recommended to use standardized calibration and sampling procedures, conduct multiple gait repetitions, and normalize by body weight to enhance data comparability and the reliability of custom insoles.

After customization, follow-up evaluation is required, and structural or material adjustments should be made if necessary to achieve therapeutic effect.