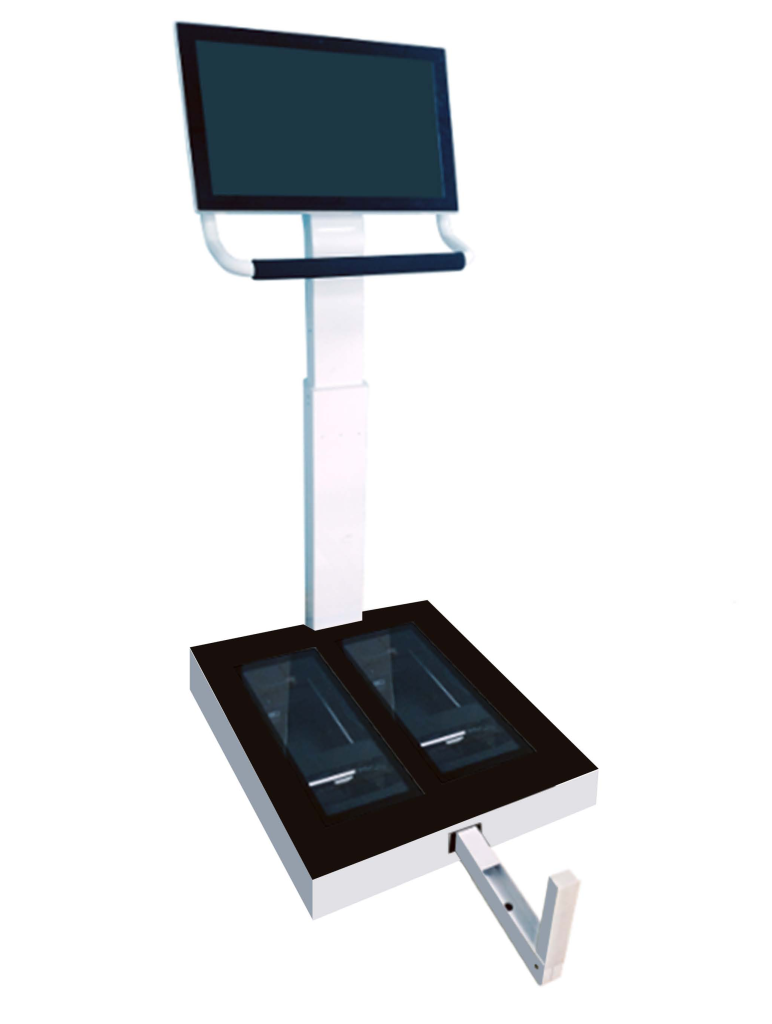

The laser application principle of 3D shoe scanner has advantages of precision control, data integrity, safety performance and structural adaptability.

The technology uses laser emission, reflection reception and spatial reconstruction algorithms to realize contactless scanning of the soles of the feet, which has obvious advantages in medical orthopedics, insole customization, sports rehabilitation and foot database construction.

1.Statement of issues

Laser measurement accuracy is high and stability is good.

Laser beam has good orientation, small divergence angles, can maintain a stable geometry and is not easily disturbed by the surrounding light.

Combined with high-resolution sensors, it can capture millimetre-or even submillimetre-scale surface contours.

Compared with structural light or camera measurements, laser scanning have less data errors in depressions, arches and complex surfaces, thus avoiding geometric distortions caused by spot deformation or shadow occlusion.

2.Data Continuity and Contour Restoration

Laser scanning is also excellent for data continuity and contour restoration.

Laser can capture high-density point cloud data on the shape of the soles of the feet in point-by-point or line-by-line scans, accurately reflecting small morphological features in key areas such as the arch, metatarsal heads and heel of the foot.

This provides a solid geometric basis for the design of customized insoles, orthotics and pressure distribution simulation. At the same time, laser scanning supports rapid reconstruction of 3D models, reduces assembly errors afterprocessing, and improves the authenticity of the entire structural remodeling process.

3.Non-Contact Measurement Performance

Laser technology has excellent non-contact measurement performance.

There is no need for direct contact with the skin during the scan to avoid data deviations due to foot posture changes, soft tissue compression or device pressure.

This is particularly beneficial for people with diabetic feet, skin ulcers or allergies as contactless scans are safe and comfortable. In addition, there is no need to use foot mold materials or physical positioning devices, which reduces cleaning and maintenance costs.

4.Adaptability to surface materials and morphology

Laser scanning is highly adaptable and less dependent on surface material and morphology.

The soles of the feet tend to have different dryness and moisture, complex textures, and translucent variations. Laser is highly reflective and anti-jamming, allowing consistent measurements even in dorsal, lateral, and other curvature transition areas.

At the same time, the device can be combined with multi-angle scanning structures or rotating platform to realize the all-round modeling of the foot.

V. Facilitation of Digital Management and Manufacturing Integration

Laser scan results facilitate digital management and manufacturing integration.

The obtained point cloud data can be imported directly into CAD/CAM systems for 3D design, simulation analysis or CNC processing. Its standardized data output format facilitates cross-system sharing and improves the efficiency of industry chain collaboration efficiency.

In custom footwear, medical devices and other industries, it can be directly connected to 3D printing equipment to speed up the production cycle.

6.Efficient Operation of Laser Scanning Equipment

Modern laser scanners can collect soles of feet data in a matter of seconds, and the process is simple and clear, without relying on the operator’s experience.

The combination of automatic calibration and image processing algorithms can effectively reduce manual intervention and improve batch processing capability.