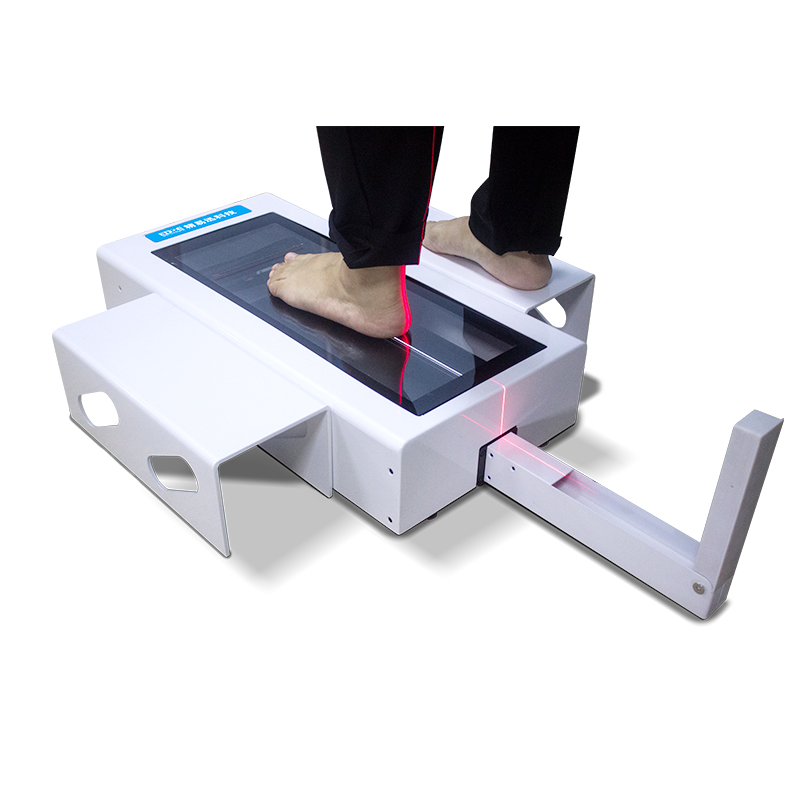

As footwear design moves toward precision and personalization, plantar laser scanners are gradually becoming a key technology for optimizing shoe sole structures. By performing non-contact 3D imaging of the user’s foot geometry, this technology rapidly acquires scientific data on sole shape, support layout, and material distribution, enabling each pair of shoes to more closely match the wearer’s actual foot shape and improve wearing comfort.

Traditional sole design often relies on standard foot lasts or average population data, which struggles to accommodate individual anatomical differences. In contrast, a plantar laser scanner can generate a highly accurate 3D foot model within seconds, clearly revealing detailed information such as arch curvature, calcaneal angle, forefoot width, and toe alignment. Designers can use this data to precisely adjust critical elements—including midsole curvature, heel cup shape, and forefoot flex point location—so the sole truly “recognizes” the wearer’s feet.

For example, for individuals with flat feet, the sole can reinforce structural rigidity in the medial longitudinal arch area to guide a normal gait pattern; for those with high arches, flexibility and cushioning thickness can be increased in corresponding midsole zones to enhance landing comfort. Moreover, for users with hallux valgus or prominent little toes, the toe box space can be moderately widened based on scan data to avoid compression and friction. This customized design, grounded in real foot morphology, significantly reduces issues caused by ill-fitting shoes—such as blisters, abrasions, and even long-term foot deformities.

In athletic footwear, this technology is applied even more deeply. Professional running shoes, basketball shoes, or hiking boots require careful balancing of flexibility, stability, and responsiveness. By using laser scanning to build athlete-specific foot databases, brands can develop sole structures better aligned with sport-specific demands—even enabling modular adjustments within the same shoe model to meet the nuanced needs of different foot types.

Furthermore, with the rapid advancement of intelligent manufacturing and 3D printing technologies today, laser scan data can be directly integrated into production systems, enabling a seamless workflow from “scanning → design → manufacturing” and greatly shortening customization lead times.