Orthopedic insoles must not only have good quality, but also accurately fit the foot. Only through professional measurement and data analysis can an insole truly tailored to the individual foot shape be made.

So how does the plantar three-dimensional laser scanner help with flat-foot correction and customization of personalized orthopedic insoles? Effective orthopedic insoles generally have the following characteristics:

I. Accurate measurement of foot structure

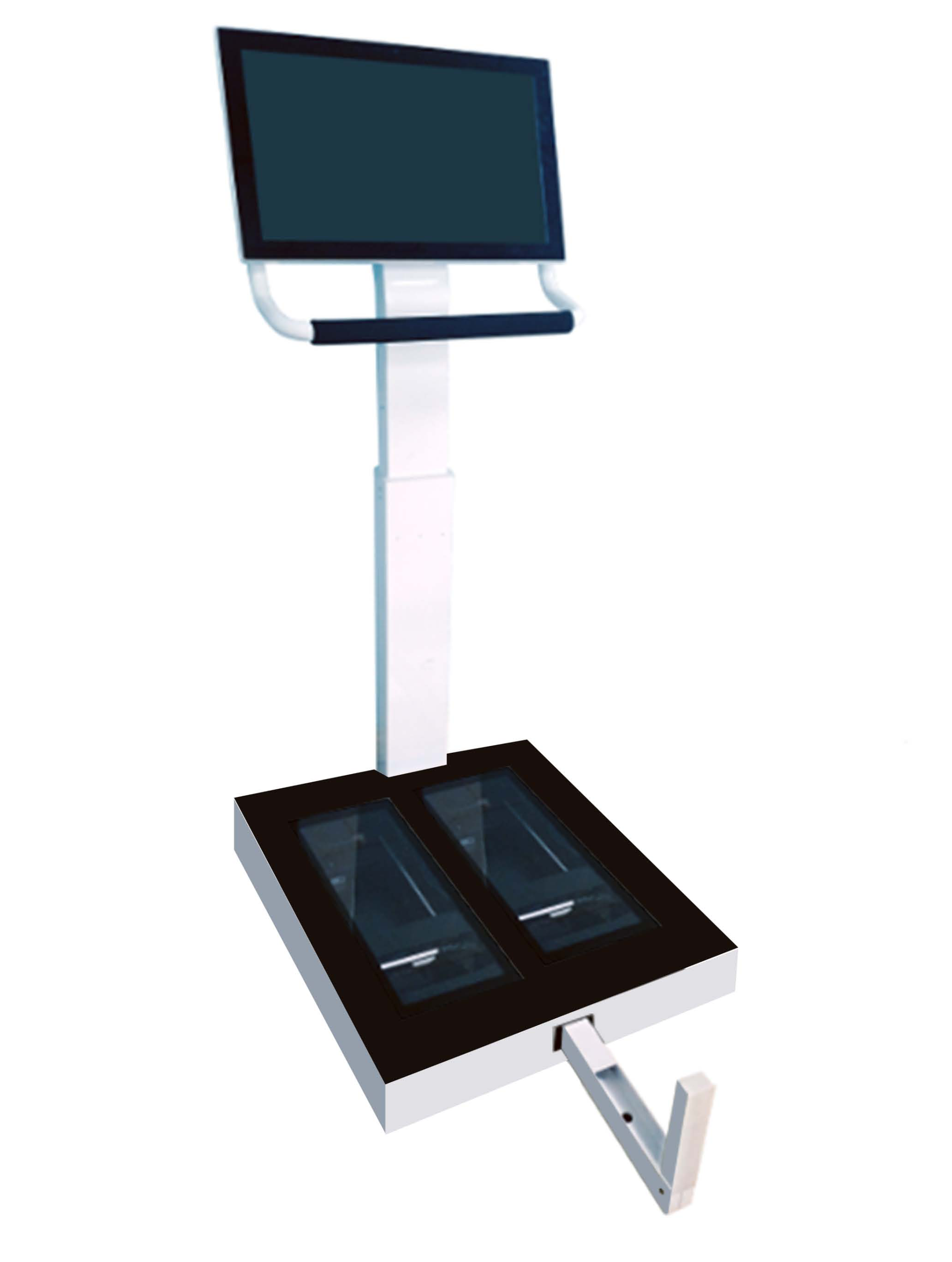

The plantar 3D laser scanner can perform a comprehensive measurement of the foot, including indicators such as foot length, foot width, foot circumference, and arch height.

For flat-foot patients, the scanner can accurately capture the location and range of arch collapse, thereby providing scientific data to ensure precise support in the design of orthopedic insoles.

Insole designers can use this information to specifically adjust the support and cushioning areas of the insole to achieve dynamic correction and reduce walking fatigue caused by flat feet.

II. Personalized correction solutions

1. Different feet

Each person’s flat-foot condition is different, mainly reflected in the degree of collapse, plantar flexibility, and gait differences.

When creating a personal foot model using 3D data, the system can customize parameters such as arch support height, forefoot width, and heel stability, enabling the insole to perfectly fit the foot and achieve the best corrective effect.

2. Adaptation to different stages

The performance of flat feet differs significantly among children, adolescents, and adults.

Scanner data can continuously update the changes in foot shape, and the insole can be adjusted, replaced, or fine-tuned in its support structure according to growth, development, or rehabilitation needs to continuously improve foot health.

III. Choice of materials and craftsmanship

1. High-quality materials

Customized insoles require materials with good elasticity, durability, and breathability, such as EVA, TPU, or memory foam.

Such materials provide sufficient support while ensuring comfort and reducing plantar pressure caused by flat feet. A breathable surface layer also reduces sweating and odor.

2. Precise craftsmanship

The manufacturing of insoles must be carried out with precise processes, mainly including cutting, forming, and assembly.

This utility model ensures that the insole size is accurate and the edges are smooth, without causing skin irritation. It is also not prone to deformation or delamination after long-term use, ensuring lasting support.

IV. Comfort and adaptability

1. High fit

Custom insoles must match the internal space of the shoe, fitting tightly when placed inside without shifting or curling.

Appropriate arch support corrects flat feet while maintaining daily walking comfort and relieving walking fatigue.

2. Easy adaptation

Since the insole is customized according to the individual foot shape, the user can adapt quickly, avoiding long periods of adjustment.

The insole provides support and correction while maintaining a natural walking feel, enabling flat-foot patients to unconsciously improve gait and foot health.